While most fishing rods today are made from carbon fibres and resin in a Chinese factory, the traditional skills of the split cane rod maker live on in the hands of a small number of artisans. One master of this art is Luke Bannister who produces beautiful rods from his workshop in Cornwall. He is currently building me a 7 foot brook rod to his superfast taper and has been sharing photographs of the building process as he progresses from the crude bamboo culm to a recognizable fishing tool and I thought it would be of interest to share some images as the work progresses.

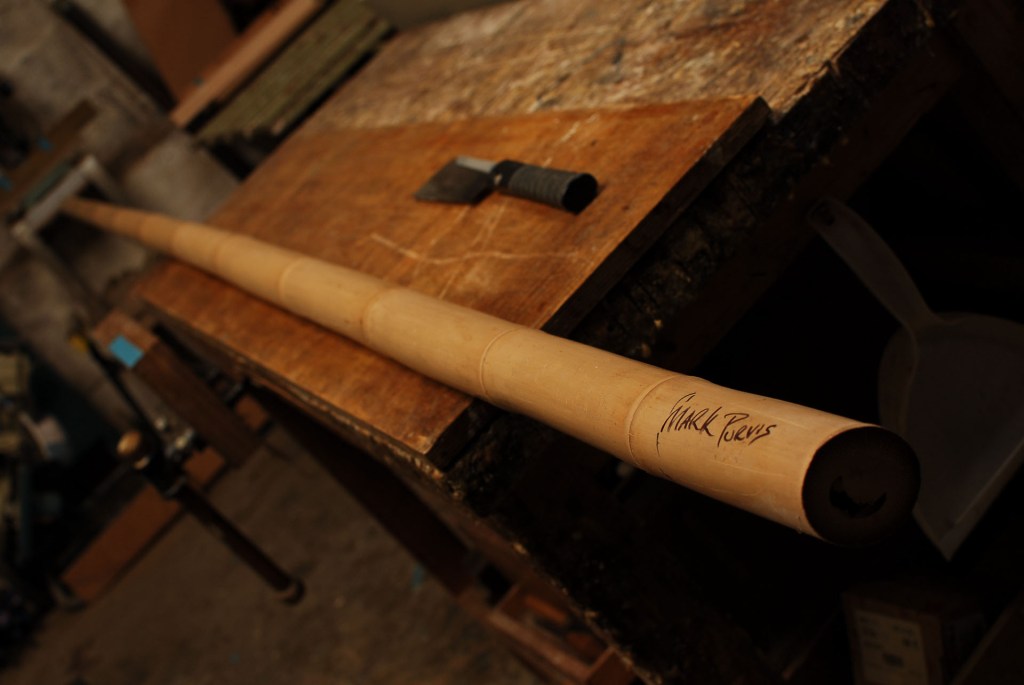

The first step is selecting the piece of bamboo.

This is cut into two sections and then split into strips.

The nodes are flattened and the best strips are selected for use in the rod build.

These strips are bevelled, heat treated and roughly tapered into their final triangular shape.

The tips then go through a final precision planning step to match them to Luke’s taper design.

The six triangular strips are then assembled into the familiar hexagonal shape of a split-cane rod ready for gluing.

To be continued…